MERCEDES UNIMOG Wiring Diagrams

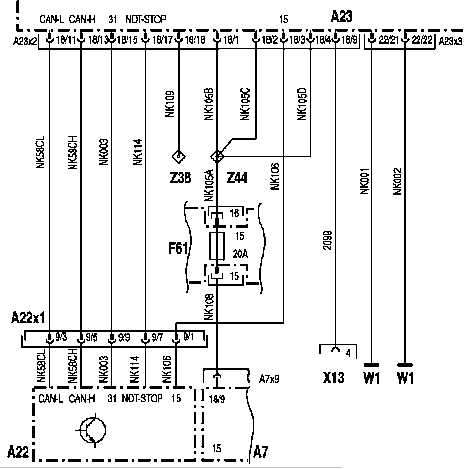

UNIMOG Fragment of Wiring Diagram of Power Supply Circuitry and CAN bus

A23: Power part 'Hydraulics'

A22: Joystick Module

A22x1: Hydraulic Joystick Connector, 9-pin

A7: Base Module

F61: Fuse, terminal 15

W1: Mass point in the center console

X13: Diagnostic Connector (pin 4)

Z38: Reference point 'Terminal W'

Z44: Reference point 15 'Hydraulics'

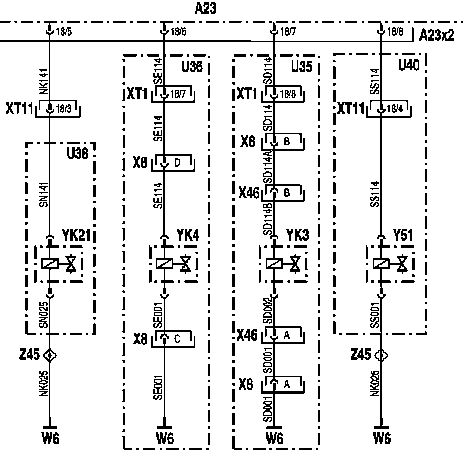

UNIMOG Fragment of Schematics of the Proportional Valves

A23: Power part 'Hydraulics'

YK21: Proportional valve, circuit 1

YK3: Proportional valve, circuit 3

YK4: Proportional valve, circuit 4

Y51: Proportional valve 'Snow Plow Unloading'

W6: Front frame mass point

XT1: Plug-in connection 'Driver's cab - chassis', 18-pin

XT11: Plug-in connection 'Driver's cab - chassis', 18-pin

X8: Hydraulics plug-in connection, 8-pin

X4b: Plug-in connection 'Proportional valve for ontura 3', 2-pin

Z45: Reference Point 31 'Hydraulic Solenoid Valves'

Note:

Proportional valve YK21 and solenoid valve YM17 cannot be installed together.

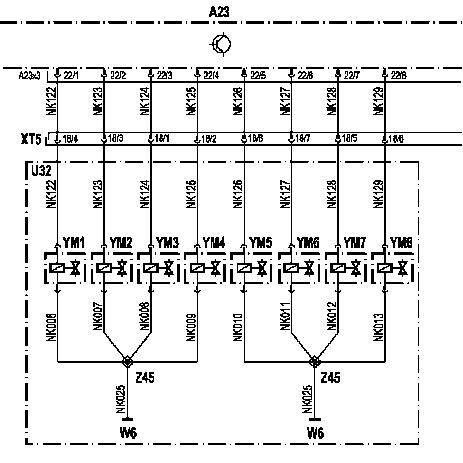

UNIMOG Part of Scheme of the Electrical Circuit of the Solenoid Valves YM1 - YM8

A23: Power part 'Hydraulics'

YM1-YM8: Solenoid Valves

W6: Front frame mass point

XT5: Plug-in connection 'Driver's cab - chassis', 18-pin

Z45: Reference Point 31 'Hydraulic Solenoid Valves'

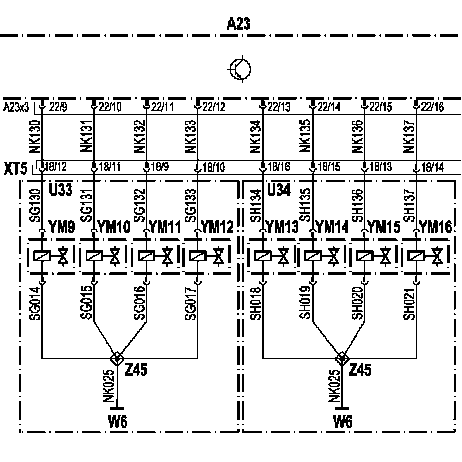

UNIMOG Part of Circuit Diagram of the Electrical Circuit of the Solenoid Valves YM9 - YM16

A23: Power part 'Hydraulics'

YM9-YM16: Solenoid Valves

W6: Front frame mass point

XT5: Plug-in connection 'Driver's cab - chassis', 18-pin

Z45: Reference Point 31 'Hydraulic Solenoid Valves'

Mercedes Unimog History

In October 1946, the first test ride took place on a prototype of an all-terrain vehicle, later called the Mercedes-Benz Unimog.

In 1951, the production was fully purchased by Mercedes and transferred to the company's plant in Gaggenau, in 1953 the car received a closed cabin.

The signature feature of the car is spring suspensions with large passages and bridges that can be tilted up to 30 degrees in any direction.